Fusion1 - Solid State Ceramic Coating

Phase 5: Protection

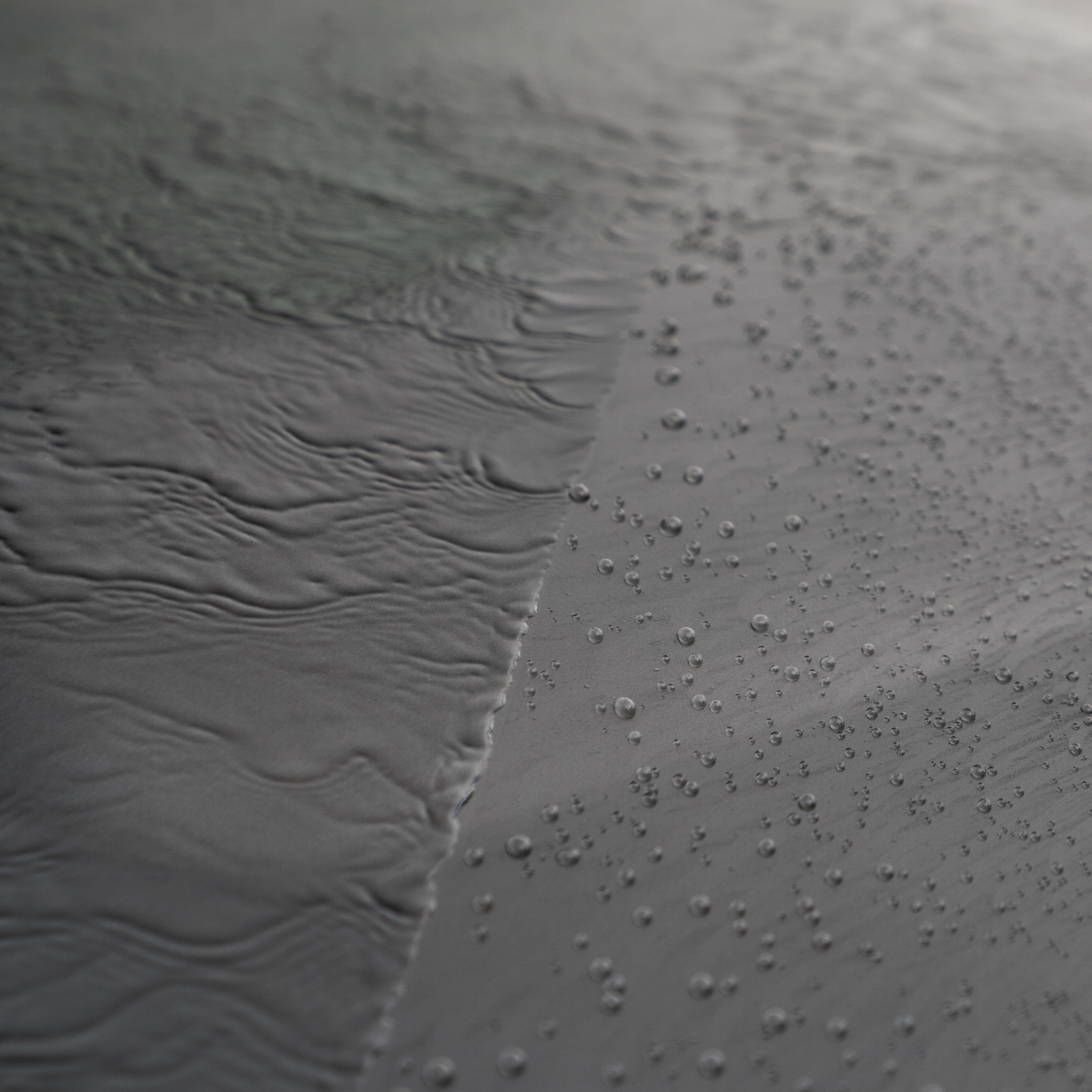

This isn’t a wax. It's the next logical step in surface protection.

Ceramic Paste is a radical reimagining of what a protective coating can be. At its core is a full-spectrum ceramic polysilazane, the same advanced chemistry found in professional-grade ceramic coatings, offering molecular-level bonding and long-term resilience.

But here’s where it gets interesting: we've combined it with five carefully selected performance additives, including solid-state SiO₂ for hardness and polyethylene for enhanced spreadability and hydrophobicity. The result is a semi-solid matrix that applies effortlessly, bonds brilliantly, and performs relentlessly.

It’s the benefits of a ceramic coating, the usability of a wax, and the satisfaction of applying something that feels as good as it performs.

Key features:

Hybrid Performance Formula – Combines the ease of a wax with the strength and longevity of a ceramic coating.

9H Hardness Rating – Cures to a rock-hard finish, achieving up to 9H on the graphite scale for exceptional scratch resistance.

Effortless Application – Smooth, semi-solid paste spreads easily by hand—no special tools or training required.

Fast Cure Time – Vehicle can be safely driven just 1 hour after application, with no compromise to performance.

Outdoor Application Friendly – Designed for real-world use, it can be applied outdoors with confidence—no garage or controlled conditions required.

Application instructions:

You don't need to be an expert to apply ceramic paste! But a few things that will help are listed below.

1. Prepare the surface – Ensure the vehicle is clean, dry, and free from previous waxes or sealants. For best results, decontaminate and polish the paintwork beforehand.

2. Apply sparingly – Using a foam or microfiber applicator, swipe a small amount of Ceramic Paste and apply in even straight lines or circles to the vehicle 1-3 panels at a time.

3. Allow to haze – Let the product cure for 10 minutes depending on ambient temperature and humidity. Avoid warm panels and direct sunlight.

4. Buff off – Using a clean, plush microfibre towel, gently buff the surface to reveal a deep gloss.

5. Curing time – Avoid contact with water for 3 hours. Vehicle can be driven 1 hour after application. Full chemical cure occurs within 72 hours. Do not wash the vehicle for at least 5-7 days after application.

It really is that easy! Ceramic paste will leave you speechless with it's ease of use and jaw dropping results. Each 200ml pot can cover around 15 vehicles making it a very cost efficient choice of you are a detailing professional.

Real world durability:

During aggressive testing the coating achieved a maximum life span of 12.5 months. This was a decontaminated and lightly polished panel on a daily use vehicle.

Other tests on badly or no preparation paintwork saw 6-8 months of strong performance.

Take your time, do the prep work and enjoy the benefits for as long as possible.

Interested in learning more? Download the Fusion1 whitepaper

Pairs well with

Delivered in 1-2 working days

Out of this world performance

Love it or refunded

Rated by professionals

Fusion1 - Solid State Ceramic Coating

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

FAQs

Please read our FAQs page to find out more.

Where are Liquid Labs products made?

We are proud to manufacture all our own chemicals in our small but well organised facility close to Sailsbury, England.

Are the products ready to use or concentrated?

Fundamentally we believe in value to our customers, with that in mind all our products are concentrated unless its not suitable, for example tar remover, fallout remover and cabin mist.

What makes Liquid Laboratories different from other detailing brands?

We strip away the fluff. Our formulas are built around radical simplicity, clean, high-performance chemistry that works hard, fast, and without compromise. No overcomplicated routines. Just results.

Are your products safe on all surfaces?

Every product is tested across a wide range of materials and finishes to ensure maximum compatibility, including ceramic coated paintwork, matte, and satin finishes. If we say it’s safe, it’s been pushed to the edge and passed.

What’s in your products, are they safe to use?

Every formula is built from high-grade, purpose-driven ingredients. We avoid unnecessary additives and design each product to deliver maximum performance with minimal complexity. We also include a handy PH guide on most chemicals for your guidance. If it’s in the bottle, it’s there for a reason.